The dispersion state of the pigment, the size and distribution of the particle size directly affect its application performance, so producers and users always strive to manufacture easily dispersible pigment products. According to the occasion of application, different dispersion equipments can be used for dispersion and grinding, usually based on mechanical dispersion.

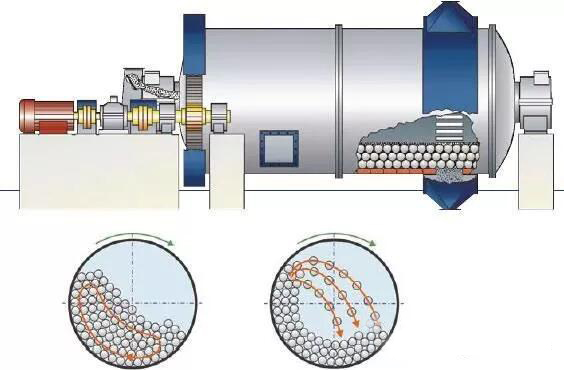

Ball mills are widely used in pigment suspensions with low viscosity to obtain highly disperse aqueous pigment dispersion, preparation of solvent-based inks, colored paints, etc. in the ink and paint industry.

The ball mill uses balls, pebble-like porcelain balls or sands with special hardness to generate shear force and impact force to cause the particles to disperse. Currently, vertical mills and horizontal sand mills are widely used.

In addition, a colloid mill can also be used to comminute the pigment particles by shear force of rotating the blade at a high speed. This device is particularly suitable for the dispersion of vat dyes, pigments in aqueous suspension media. Typical equipment such as high-speed toothed dispersers , three-roll mills, etc.