Welcome to view our artical about the PVA waste water treatment.Today is the second part of the Physical law method.

Physical law-2:Salting gel method/Membrane separation method

1.4, Salting gel method

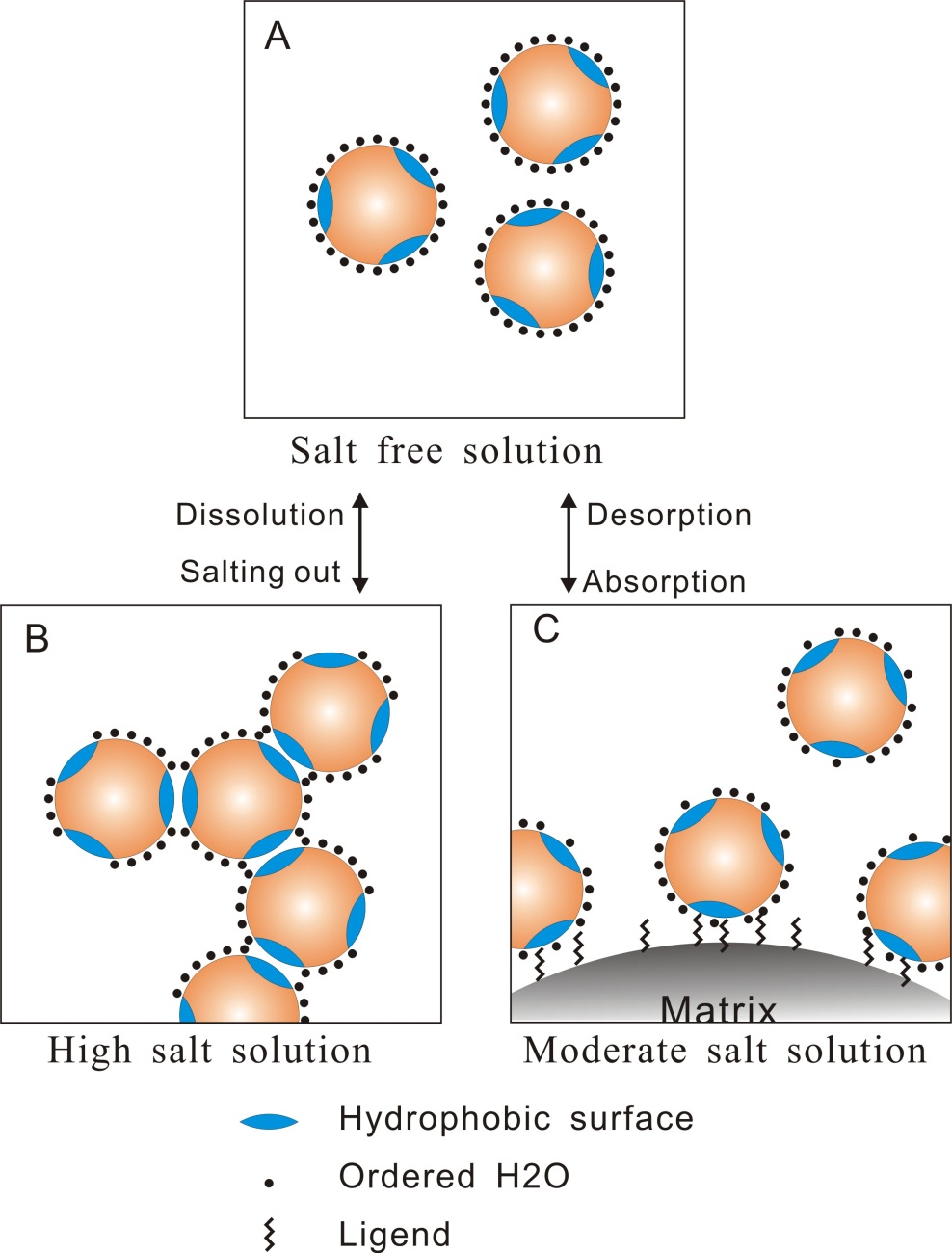

In the PVA wastewater treatment process, salting gel method can be used. That is, according to the characteristics of PVA, the salting-out agent sodium sulfate and the gelling agent borax are added into the waste water so that the borax reacts with the PVA molecules to form the PVA-borax diol type structure. Under the action of Na + and SO42-, Through its powerful water and ability to absorb a large amount of water around, making PVA dehydration from the precipitation of waste water.

The results showed that the dosage of sodium sulfate and borax were 14g / L and 1.4g / L respectively when the concentration of PVA in wastewater was 12g / L, and the reaction time was controlled for 20min , The reaction temperature is 50 ℃, the initial pH of the solution is 8.5 ~ 9.5, the recovery rate of PVA is more than 90%.

Polyvinyl alcohol in textile printing and dyeing desizing wastewater was treated and recovered by chemical coagulation method. PVA and PVA recovery rate and COD removal rate in the productive scale recovery wastewater were all successfully reached about 80%.

Study on the Recovery of PVA in Desizing Wastewater by Condensation. The results showed that the recovery rate of PVA batch reaction was up to 90%. On this basis, the PVA continuous recovery process was achieved with the recovery rate of 80%.

1.5, Membrane separation method

Membrane separation technology acts through the separation of waste water pollutants, concentration, recycling to achieve the purpose of purification of sewage, mainly microfiltration, ultrafiltration, nanofiltration and reverse osmosis. Membrane separation method has the advantages of energy saving, no phase change, simple operation, simple equipment, etc., and recyclable materials can be recycled. It has been proved that it is practicable in the treatment of printing and dyeing wastewater.

If the PVA slurry in the desizing wastewater can be recycled, it can save resources and costs, create economic benefits, reduce the difficulty of wastewater treatment and reduce emissions. Microfiltration and ultrafiltration are based on the separation mechanism of sieving, which can trap suspended particles and macromolecules in the desizing wastewater, but can not separate the ions in the water. In the process of ultrafiltration, the liquid flows through the membrane surface under the pressure. Small solutes and water which are smaller than the membrane pores become the purifying liquid through the water membrane. The substances larger than the membrane pores such as PVA are intercepted and discharged as the concentrated liquid. The PVA Concentrate to the appropriate concentration can be re-used desizing, cleaning fluid can also be used for desizing.

Membrane separation technology is a cleaner production technology, with good environmental and economic benefits, but the level of application of membrane technology in China and the world advanced level there is still a gap, the urgent need to develop high-performance separation membrane and large membrane devices. At present, the performance of various films is not yet stable, easy to plug the membrane pore, membrane system, high cost, short life. So how to choose the right membrane, improve membrane performance, membrane pollution control and reduce costs is the key to widespread implementation of this method.

Using membrane-type membrane ultrafiltration device PVA can be recovered from PVA desizing wastewater test. The results show that this method is feasible. Under the condition of controlling the temperature of the feed liquid at 60-80 DEG C and the operating pressure of 0.4-0.6MPa, the polyvinyl alcohol wastewater with the concentration of 0.5% -1.0% can be concentrated to 10.0% and the removal rate of the polyvinyl alcohol can be above 95% The polyvinyl alcohol slurry after deployment, can be used in the production, to meet the requirements of the production process. Zheng Huidong textile dyeing and printing plant for the discharge of PVA-containing desizing skin water, the use of hollow fiber ultrafiltration membrane experimental device for its treatment test. The results show that the treated wastewater meets the water standard and can be recycled.

Next month,we will introduce some Chemical oxidation method to deal.